Oxygen sensitive nanoparticles used for 3D printing of complex tissue-like structures

Posted: 2 October 2018 | Drug Target Review | No comments yet

Researchers have implemented oxygen sensitive nanoparticles into a gel material that can be used for 3D printing of complex, biofilm and tissue-like structures…

An international team of researchers have implemented oxygen sensitive nanoparticles into a gel material that can be used for 3D printing of complex, biofilm and tissue-like structures harbouring living cells as well as built-in chemical sensors.

Professor Michael Kühl at the Department of Biology, University of Copenhagen explains: “3D printing is a widespread technique for producing the object in plastic, metal, and other abiotic materials. Likewise, living cells can be 3D printed in biocompatible gel materials (bio-inks) and such 3D bioprinting is a rapidly developing field, eg, in biomedical studies, where stem cells are cultivated in 3D printed constructs mimicking the complex structure of tissue and bones. Such attempts lack online monitoring of the metabolic activity of cells growing in bio-printed constructs; currently, such measurements largely rely on destructive sampling. We have developed a patent-pending solution to this problem.”

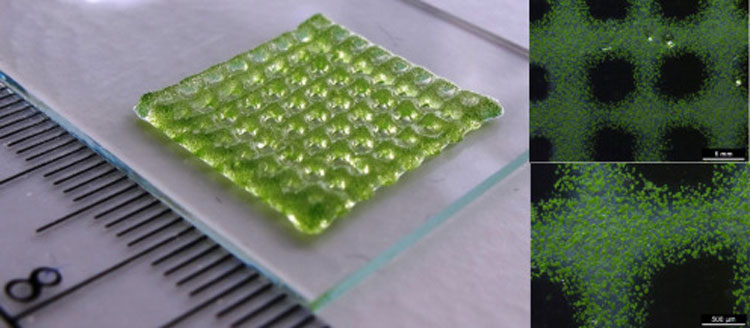

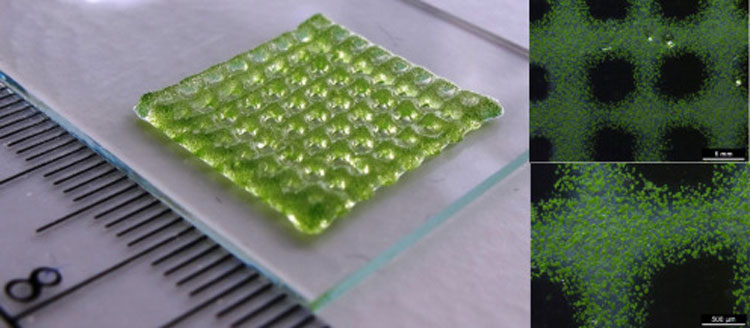

3D bio-printed structure containing green algae (Chlamydomonas) in a hydrogel. Credit – Anja Lode, TU Dresden

The group developed a functionalised bio-inks by implementing luminescent oxygen sensitive nanoparticles into the print matrix. When blue light excites the nanoparticles, they emit red luminescent light in proportion to the local oxygen concentration – the more oxygen the less red luminescence. The distribution of red luminescence and thus oxygen across bio-printed living structures can be imaged with a camera system. This allows for online, non-invasive monitoring of oxygen distribution and dynamics that can be mapped to the growth and distribution of cells in the 3D bio-printed constructs without the need for destructive sampling.

Prof Kühl continues: “It is important that the addition of nanoparticles doesn’t change the mechanical properties of the bio-ink, e.g. to avoid cell stress and death during the printing process. Furthermore, the nanoparticles should not inhibit or interfere with the cells. We have solved these challenges, as our method shows good biocompatibility and can be used with microalgae as well as sensitive human cell lines.”

The recently published study demonstrates how bio-inks functionalised with sensor nanoparticles can be calibrated and used e.g. for monitoring algal photosynthesis and respiration as well as stem cell respiration in bio-printed structures with one or several cell types.

“This is a breakthrough in 3D bioprinting. It is now possible to monitor the oxygen metabolism and microenvironment of cells online, and non-invasively in intact 3D printed living structures” says Prof. Kühl. “A key challenge in growing stem cells in larger tissue- or bone-like structures is to ensure a sufficient oxygen supply for the cells. With our development, it is now possible to visualise the oxygen conditions in 3D bio-printed structures, which e.g. enables rapid testing and optimisation of stem cell growth in differently designed constructs.”

The team is very interested in exploring new collaborations and applications of their developments.

Prof Kühl ends: “3D bioprinting with functionalised bio-inks is a new powerful technology that can be applied in many other research fields than biomedicine. It is e.g. extremely inspiring to combine such advanced materials science and sensor technology with my research in microbiology and biophotonics, where we currently employ 3D bioprinting to study microbial interactions and photobiology.”

The work has been published in the journal, Advanced Functional Materials.

Related topics

3D printing, Biofilms, Bioprinting, Organoids, Stem Cells

Related organisations

Copenhagen University, Technical University of Dresden

Related people

Professor Michael Kühl